Simplify Buffer Preparation

The volume and number of buffers for a typical downstream process can be considerable.

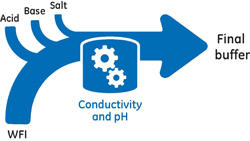

Preparation of these buffers is a challenge that in-line conditioning can overcome. Inline conditioning simplifies buffer preparation and offers significant reduction in number of tanks, buffer solutions, and floor space needed. The technology also limits manual preparation time. With in-line conditioning, buffers are prepared from concentrated stock solutions of salt and water for injection (WFI) plus an acidic and a basic component (e.g., NaH2PO4 and Na2HPO4, respectively). GE's extensive HyClone™ buffer and process liquids portfolio include stock solutions suitable for in-line conditioning. Both standard formulations and customized solutions are available.

Preparation of these buffers is a challenge that in-line conditioning can overcome. Inline conditioning simplifies buffer preparation and offers significant reduction in number of tanks, buffer solutions, and floor space needed. The technology also limits manual preparation time. With in-line conditioning, buffers are prepared from concentrated stock solutions of salt and water for injection (WFI) plus an acidic and a basic component (e.g., NaH2PO4 and Na2HPO4, respectively). GE's extensive HyClone™ buffer and process liquids portfolio include stock solutions suitable for in-line conditioning. Both standard formulations and customized solutions are available.

To learn more about how buffer preparation can be made simpler, and other ways to gain efficiency in downstream bioprocesses, download the white paper: Unlocking the Potential for Efficiency in Downstream Bioprocesses.