Pharmaceutical change management processes extend to the materials and services employed to manufacture and test drug products, necessitating the need for an effective supplier-initiated change (SIC) management process.

Pharmaceutical and biotechnology companies making products for human use have an obligation to ensure that their products are safe, effective, meet established regulatory expectations and licenses, and are available to the patients who rely on them. Pharmaceutical change management processes extend to the materials and services employed to manufacture and test drug products, necessitating the need for an effective supplier-initiated change (SIC) management process. This article provides an overview of the pharmaceutical SIC process, including a discussion on the need for control of SICs, a review of change notification scope and content, and a summary of how SICs are typically evaluated, managed, and closed.

Biotech and pharmaceutical products, if defective, have a high potential to cause harm to the patients who are using them. As a result, companies making these products perform extensive studies to validate that the materials, equipment, and processes used for manufacturing consistently produce products that meet specifications upon release and throughout their labeled shelf life.

One of the cornerstones of consistency in any process is change control. Pharmaceutical manufacturers’ change-control systems are designed to ensure that any changes to raw materials, product contact materials, manufacturing methods, product tests, and production equipment among others are understood, evaluated, and approved prior for use in manufacturing. In addition, drug manufacturers must ensure that regulatory authorities (e.g., FDA, European Medicines Agency [EMEA], and other Boards of Health) are updated on changes associated with their manufacturing licenses and product dossiers.

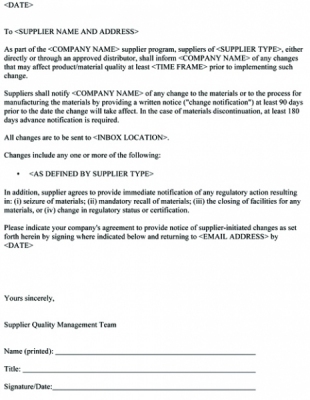

Suppliers providing services or materials that are employed for manufacture of human use products are also expected to have an established change-control system. These systems should provide for reporting applicable changes to their pharmaceutical customers. These change notifications, when received, are evaluated to determine the impact on the manufacturing process for the drug or biologic product.

Change Notification Scope and Content

In general, biotech and pharmaceutical manufacturers need to be aware of any change that might alter the properties or performance of a material used in manufacturing or testing, or which will impact manufacturing-related documentation. These changes need to be known prior to implementation so that manufacturers can fully evaluate them and have time to plan for and qualify the change.